TAPER-SLOT® Vibratory Screen

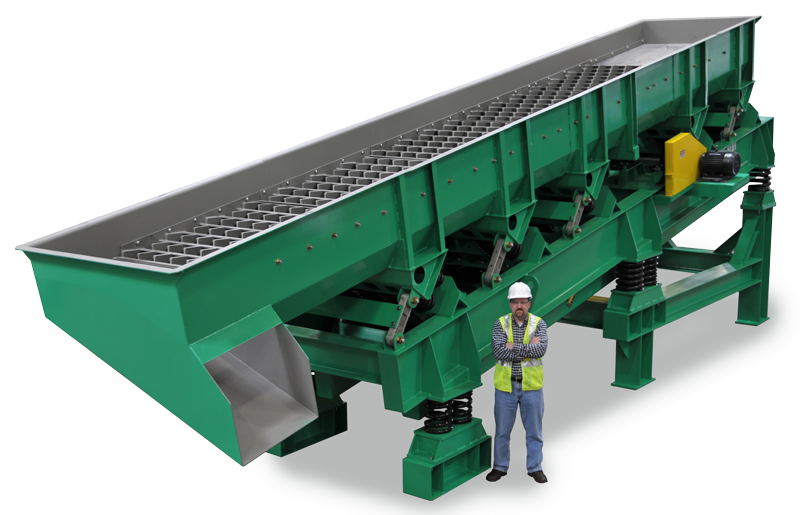

Battleship Tough Vibratory Finger Screen

The innovative long-stroke TAPER-SLOT® Vibratory Screen is designed to excel in challenging applications that conventional vibratory screens cannot handle. It is ideally suited for non-uniform and difficult-to-screen bulk materials. The combination of long-stroke vibratory action and screen design provides smooth, continuous, material flow and efficient separations.

For stickier applications, including C&D materials, you can now select a SUB-PAN FREE® long-stroke TAPER-SLOT® Screen with classified fractions discharging directly into a bunker or onto a take-away conveyor. The SUB-PAN FREE® option is the right choice for sticky applications, eliminating material build-up, wear, and related sub-pan maintenance items.

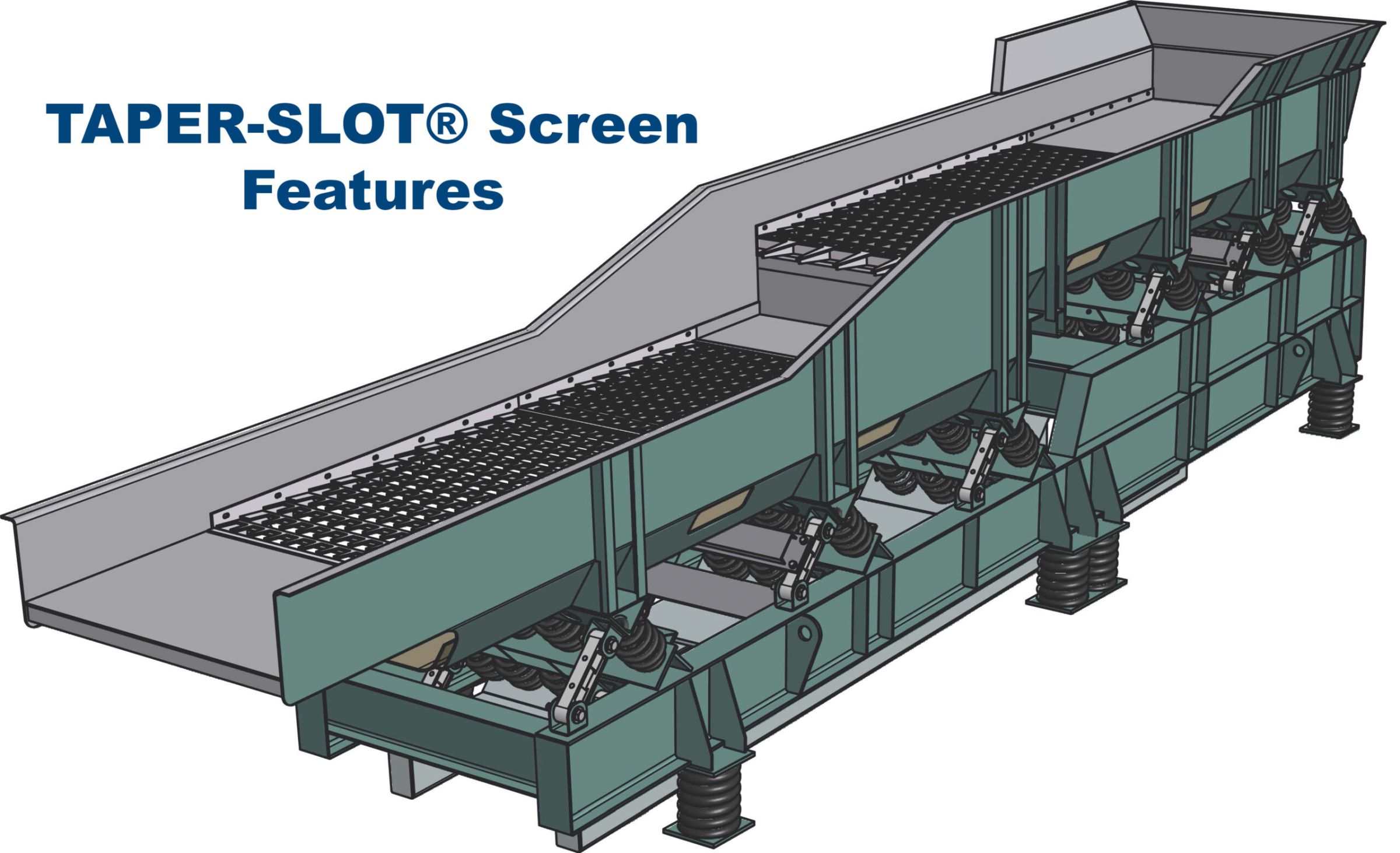

Features

Hover over features to see descriptions

Load Plate

Vertical Drop

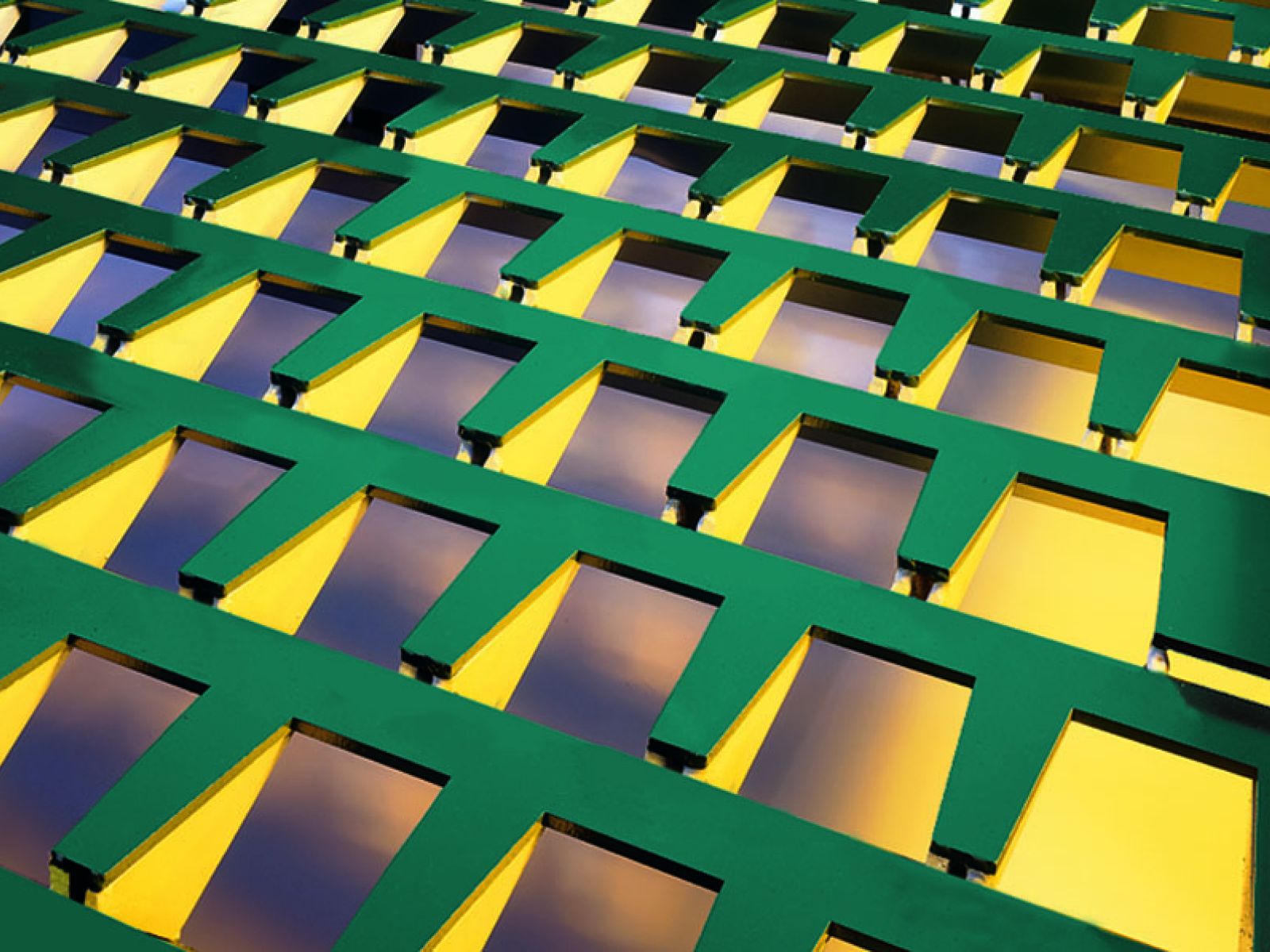

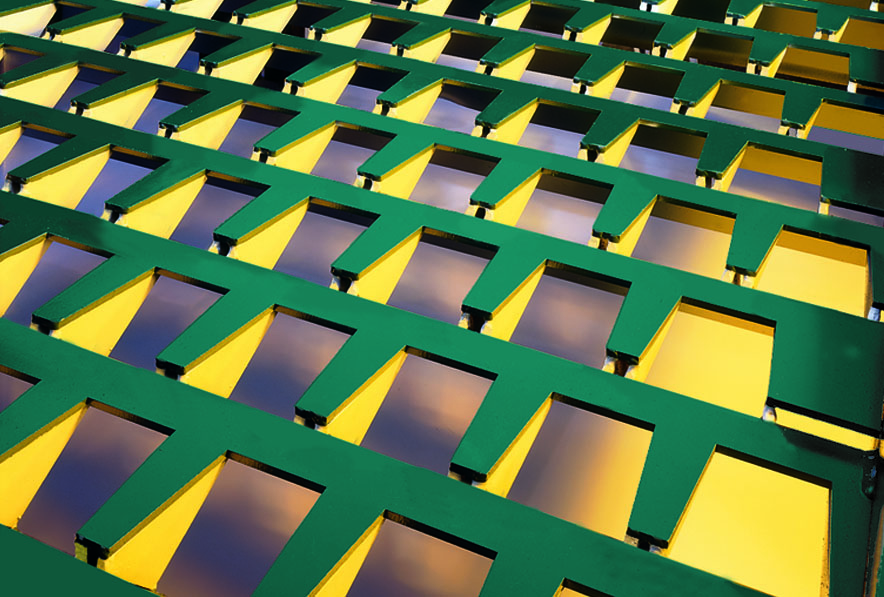

TAPER-SLOT® Screen

The combination of long stroke vibratory action and screen design provides smooth, continuous, material flow and efficient separations. Longer pieces that initially enter an aperture don’t free-fall into the screened fraction but rather contact the formed “tail” portion of the TAPER-SLOT® Screen and convey downstream for discharge with the oversize.

Collecting-Pan Access / Clean-Out Port

Vibration Isolation

Collecting-Pan & Liner

Stabilizer Arms

Long Stroke Reaction Spring

Sympathetic Balancer

Benefits

Unlike conventional vibratory finger screens, the highly efficient TAPER-SLOT® Vibratory Screen, with lateral wedge members offers the following benefits for superior screening performance:

Conventional Finger Screen

TAPER-SLOT® Screen

Hang-Up Elimination

Lateral wedge deflectors prevent material from shifting laterally and catching under or wrapping around finger tips, thus allowing the screen to remain clean for maximum screening efficiency.

Accurate Sizing

Lateral wedge deflectors prevent longer, often oversized materials from shifting sideways under a finger tip and falling into the accepts.

Ultra-Rigid

Lateral wedge deflectors prevent undesirable “finger–bending” and function as gussets under each finger to provide the ultimate in rigidity for long screen life.

Self-Relieving

Staggered fingers and divergent openings allow particles the opportunity to self-relieve / cam-out.

Advantages

- No plugging, blinding, or hang-ups common to conventional perforated or wire mesh screens

- Accurate sizing

- Screen multiple sizes per unit

- High throughput performance

- Easy to install, maintain, and operate

- Screen sections are modular and easily changeable

- Eliminates belt conveyors

- Does not “fluff” or increase material volumes of lightweight materials such as paper

- No periodic stops or re-tunes due to material wrapping around fingers, discs, shafts, gears, chains or sprockets

- Safe. Unlike trommels (rotating perforated cylinders), the TAPER-SLOT® Vibratory Screen isn’t dangerous to fix and maintain

- Minimum horsepower and operating costs

- Distributes material flow at a regulated rate to downstream equipment such as a sort line or grinder

- Each TAPER-SLOT® Vibratory Screen is customized to meet application requirements including apertures with optimized open area

Material Applications

- Construction & Demolition (C&D)

- Scrap Tires

- Landfill Reclamation

- Compost

- Auto Shredder Residue (ASR)

- Wood Waste

- Aggregate & Dirt

- Commingled Recyclables

- Municipal Solid Waste (MSW)

- Commercial Waste

- Metal from Bottom Ash

- Glass, Plastics, & Metal

- Refuse Derived Fuel (RDF)

- Electronic Waste (E-Scrap)

- And many other materials