Vibratory Conveyors

Uncompromised Excellence

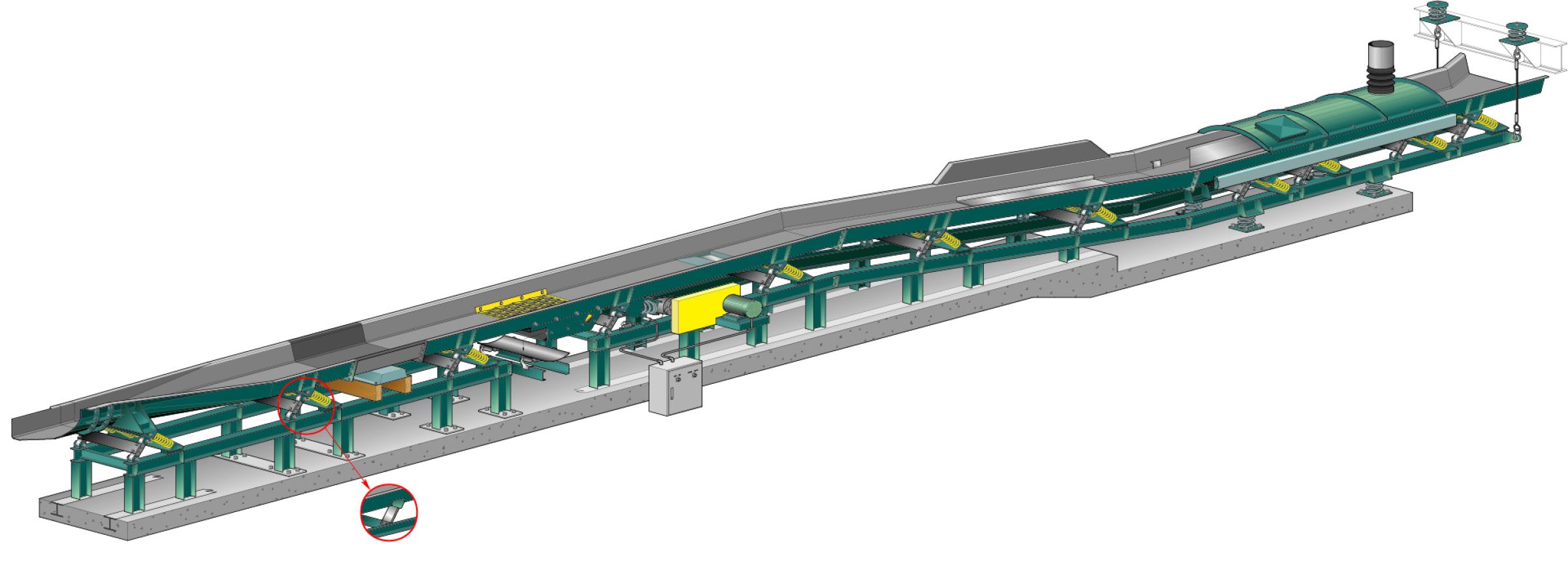

ACTION’s natural frequency vibratory conveyors are made to order for the efficient transport of bulk materials in a wide range of widths and lengths to suit the application. Process features such as screens, metal detectors, dividers, skirts, custom spouts, multiple discharge points, varying widths, hoods, and liners can be integrated to suit the application.

Features

Hover over features to see descriptions

REMOVABLE SPOUT & TAKE-OUT

INSTALLATION OPTIONS

STRUCTURAL STEEL BASE

GRADUAL TRANSITION

NON-METALLIC SECTION & METAL DETECTOR

ADVANCED CONTOUR COMPOSITE SPRING

TAPER-SLOT® SCREEN

(U.S., CND & EC PATENT NOS. 5,746,322, 2,206,981 & 97304642.8)

For many materials, the patented TAPER-SLOT® Screen is the preferred alternate to inherently problematic classification equipment such as finger Screens, perforated screens, wire mesh screens, disc screens, and rotary trommels. Without cross wires, rods, or high wear rotating discs to catch or restrict material flow, the TAPER-SLOT® SCREEN can quickly classify materials with less blinding for accurate and continuous high volume screening. All screen sections are modular, easily changeable, and available in wide range of materials.

FLEXIBLE LINER

HIGH GRADE FASTENERS

CUSTOM DISCHARGES

BASE TAKE-OUT SECTION

NEW GENERATION STROKE PLATE

CENTRAL LUBRICATION

REUSABLE VIBRATORY TORQUE NUT

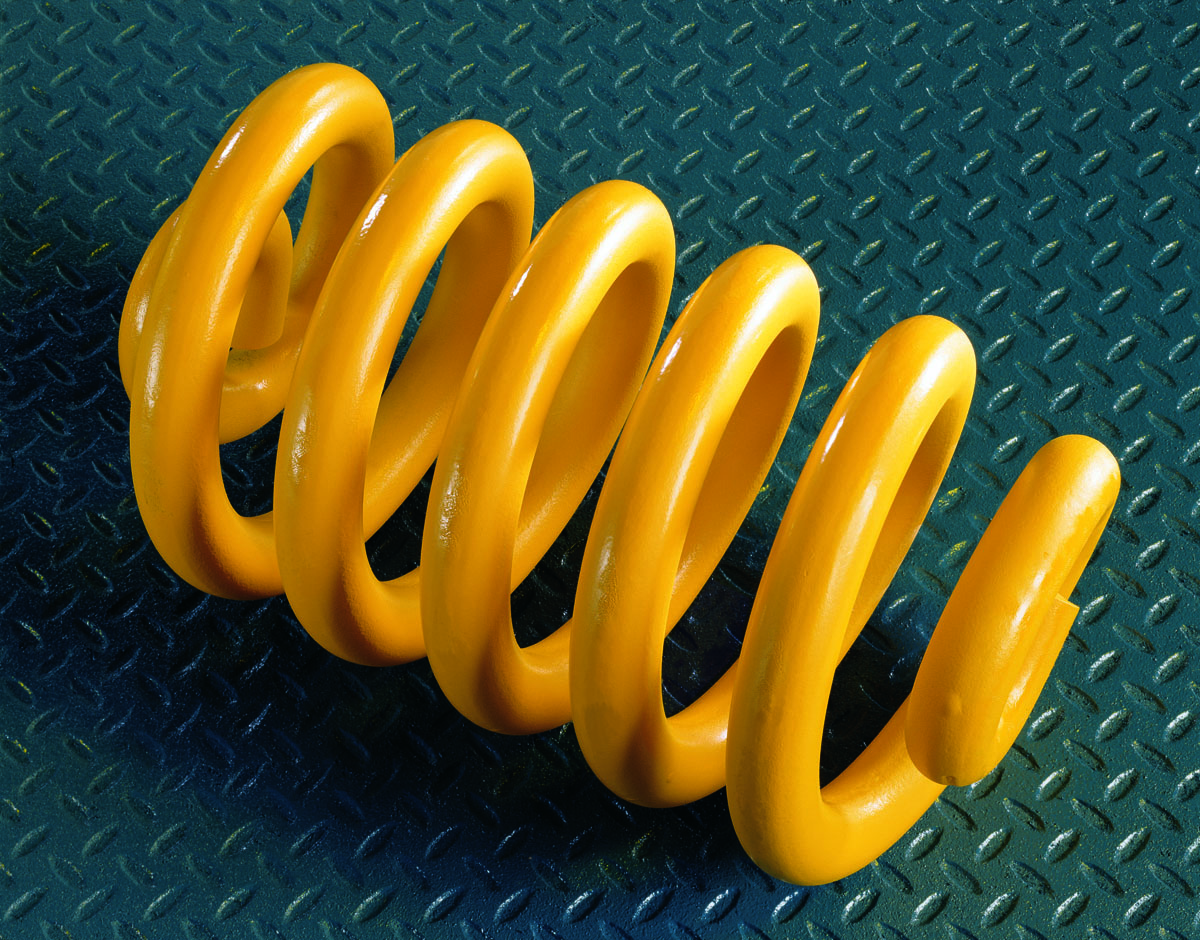

ACTION COIL SPRING DRIVE

STROKE CONTROL UNIT – SCU

(U.S. Patent No. 5,944,170)

The SCU protects your investment through the active management of vibratory stroke amplitude, eliminating costly problems attributable to undesirable, unnoticed, irregular, and uncontrolled operating variables. By continuously monitoring and automatically controlling stroke, a mechanically sound conveyor is maintained under all operating conditions without unexpected stroke mandated shutdowns. The SCU is an important link in centralized process automation and is ideally suited for abnormal operating conditions or when conveyors are inaccessible.

POWERFUL MAGNETIC TRAP

PREMIUM EFFICIENCY EQP III TEFC MOTOR, SLIDE BASE, & OSHA APPROVED GUARD

DYNAMIC BALANCING

SUPPORT STRUCTURE

BOLTED SECTIONS

TROUGH w/ COMPLETE GUSSETING

SOLID STEEL STABILIZING CROSS TIES

LONG STROKE REACTION SPRINGS

SKIRTING / HIGH SIDES

REPLACEABLE IMPACT / WEAR LINER

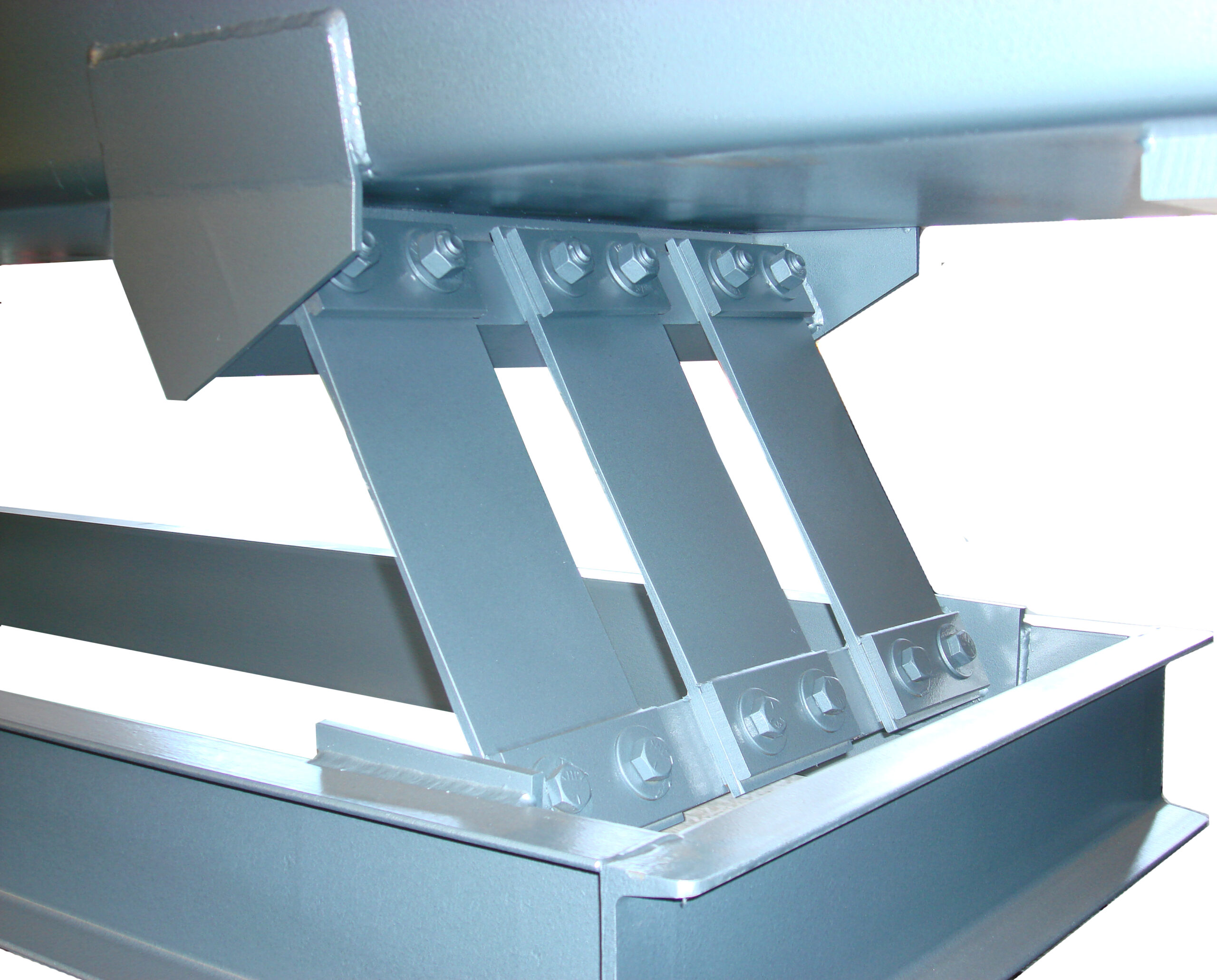

DURABLE CAST ALUMINUM STABILIZER ARMS

RAIN DRAIN

DIVIDER & LANES

ISOLATION SPRINGS

REMOVABLE HOODING

IN-FEED OVERHANG & FLARE

ISOLATION SPRINGS

Benefits

Components

ACTION uses only high-quality robust components on our vibrating conveyors for maximum reliability in the harshest of environments.

Advantages

Contour Spring Vibrating Conveyors

The ACTION Contour Composite Spring is another example of a premium component that sets a high standard in terms of integrity and function on our vibrating conveyors. This specially contoured spring, with patented geometry for a more even distribution of stress (thicker on the ends and thinner in the middle), transfers energy from the unit drive to the pan, and ultimately, to the product. ACTION’s Contour Composite Spring boasts a substantially longer life than constant thickness designs and is stronger than steel with excellent tensile strength, stiffness, modulus, and fatigue resistance.

It is now possible to nearly eliminate failures due to inherent high-stress concentrations at non-moving clamp bar edges common to constant thickness springs or slats.

Material Applications

ACTION vibrating conveyors are used to move materials from one place to another and can be individually tailored for a wide range of process applications with coil spring or contour composite spring components. ACTION gear can be found in a wide range of industries:

- Wood / Forest Products

- Agriculture

- Food Products

- Gypsum

- Plastics

- Scrap Tires

- Wood Wastes

- Chemicals

- Auto Shredding Industry

- Aggregates

- Minerals

- Recyclables

- Glass

- Foundry Materials (castings, sand, aluminum, axle spindles, etc.)