Vibratory Feeders

ACTION offers a wide range of performance-proven vibratory feeders. Like all ACTION vibratory equipment, each feeder is engineered with appropriate stroke, R.P.M., and declination for efficient conveying and metering of bulk materials. Mating hoppers, gates, screen sections, distribution domes, and other features can be integrated.

Features

Hover over features to see descriptions

Feeder Trough Material & Shape

Vibration Isolation

Supports

In-feed Configurations

Drive Adapter

Vibration Isolation

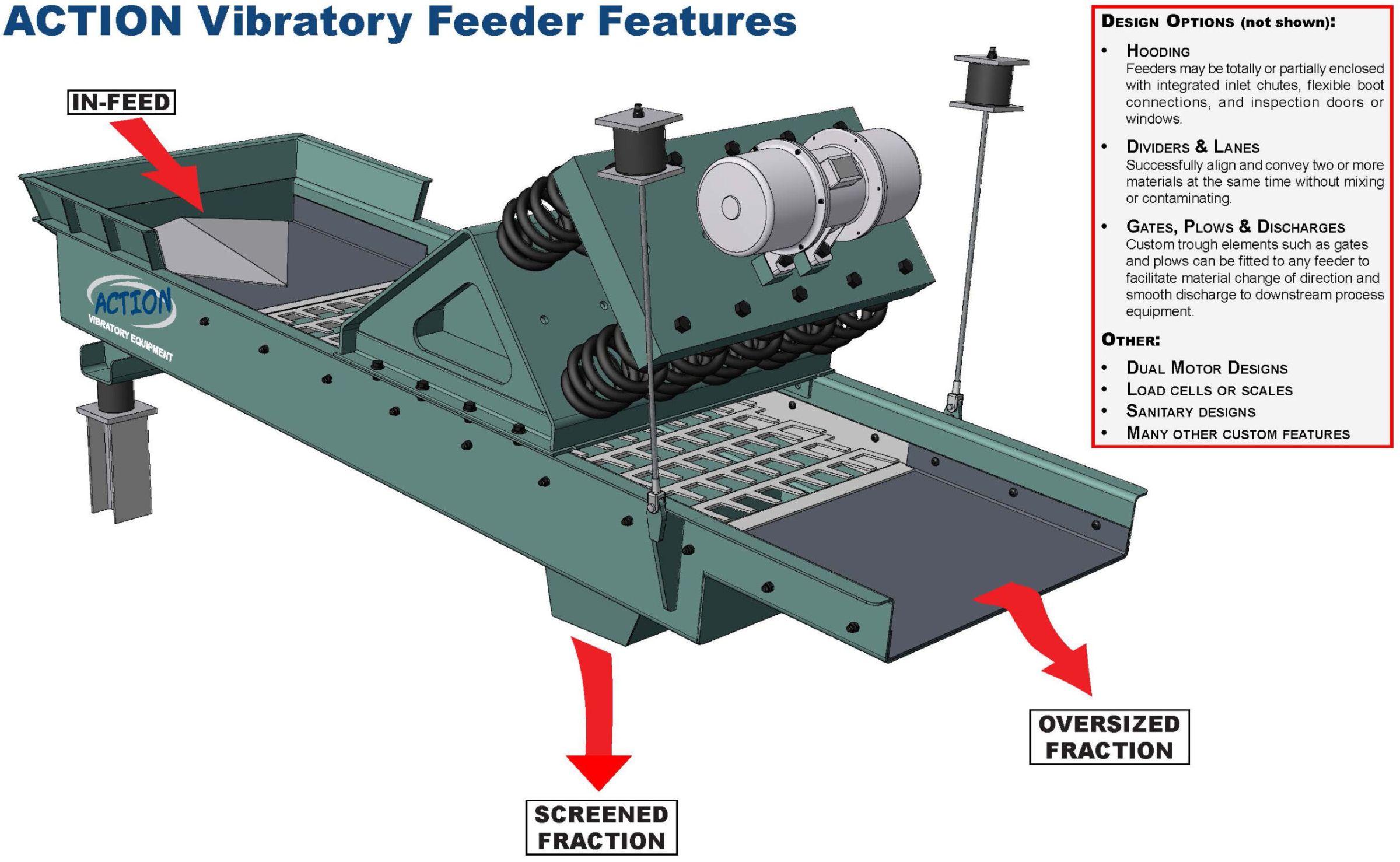

Optional Screen Section

Screening while conveying adds utility. All screen sections are modular, easily changeable, and available in a variety of media types such as:

- TAPER-SLOT® Screen

- Wire Mesh

- Perforated Plate

- Wedge Wire

- Polyurethane or Rubber

- Rod or Bar Elements

- Grizzly Scalper

- and more…

Centrifugal Feeder Motor

Impact / Wear Liner

Benefits

Dynamic Balancing

Eliminates costly and bulky support structures.

Rugged Construction

Frames are rigid with longitudinal and transverse reinforcing members.

Dependable Long Service Life

ACTION vibratory feeders are manufactured to exacting tolerances and provide years of reliable service in the toughest environments.

High Capacity

High intensity vibration increases material flow rates and productivity.

Fewer Parts

No gears, V-belt drives, bearings or bushings. Fewer parts minimize maintenance.

Advantages

Base Activated Feeder

- Consistent strokes on pan and base, side-to-side and end-to-end. There is no sensitive overhung exciter prone to rocking and side frequencies.

- Negligible dynamic loads. No need for additional, often costly, sympathetic base systems for elevated installations. Unit supports can be minimized.

- Longer pan strokes on the order of 2x

- 2-Mass Natural frequency design with single base-mounted low horsepower centrifugal motor for energy efficiency

- No complex drive adapter gusset matrix with significant welding

- No concentrated drive adapter stresses typical of a direct drive “brute force” dual motor feeder.

- Reaction springs are evenly distributed and easier to access than tightly packed overhung exciter designs.

- Feed rate can be adjusted electrically via a VFD.

Two Mass Feeder

Reduce Energy Consumption

ACTION’s two-mass natural frequency, single motor, vibrating feeders generate circular motion and use substantially less horsepower to achieve the same amount of work as dual motor (direct drive or brute force) designs.

Full Size Hopper Openings

Two-mass feeders permit larger hopper openings and promote material flow with less chance for jamming or bridging in hopper throats.

Automatic Load Compensation

Two-Mass feeders are tuned to increase vibratory force to compensate for material head loads, without dampening, for consistent material feed-rate control.

Direct Drive Feeder

Practical and easy to use, ACTION single-mass dual motor vibrating feeders provide linear motion and are a practical option for many applications. Direct Drive Feeders are driven by two counter-rotating vibrators which are the only mechanical working parts on the unit.

Under Mill Oscillator & Feeder

Built Like a Tank Our ultra tough and durable under mill oscillators and feeders are designed for the harsh environment under your hammermill shredder.

- Extra heavy duty replaceable liners

- Rear mounted drive for easy maintenance access

- Explosion stops to protect components

Coil spring and direct-drive designs are available.

VIBRA-DISCHARGER®

The VIBRA-DISCHARGER® is a high-capacity vibratory feeder for the activating, metering, and feeding of granular bulk materials from hoppers, bins, and silos. Materials discharge vertically to a take-away conveyor below with symmetrical product distribution.Click here for more information

Material Applications

- Eddy Current Separator (ECS) Feeders

- De-Watering Feeders

- Long Stroke Feeders

- Tube Feeders

- Grizzly Scalping Feeders

- Screening Feeders

- Single & Dual Magnetic Drum Feeders

- Container Loading Feeders

- Weigh Feeders

- Batch Feeders

- Grizzly Feeders

- Crusher Feeders

- Shakeouts

- Dosing Units

- Undermill Feeders

- Transfer Point Feeders – Cleanly align & turn materials while eliminating higher maintenance belts Transverse Spreading

- Feeders – Accepts narrow material flows & spreads product evenly across the next, wider item of process equipment